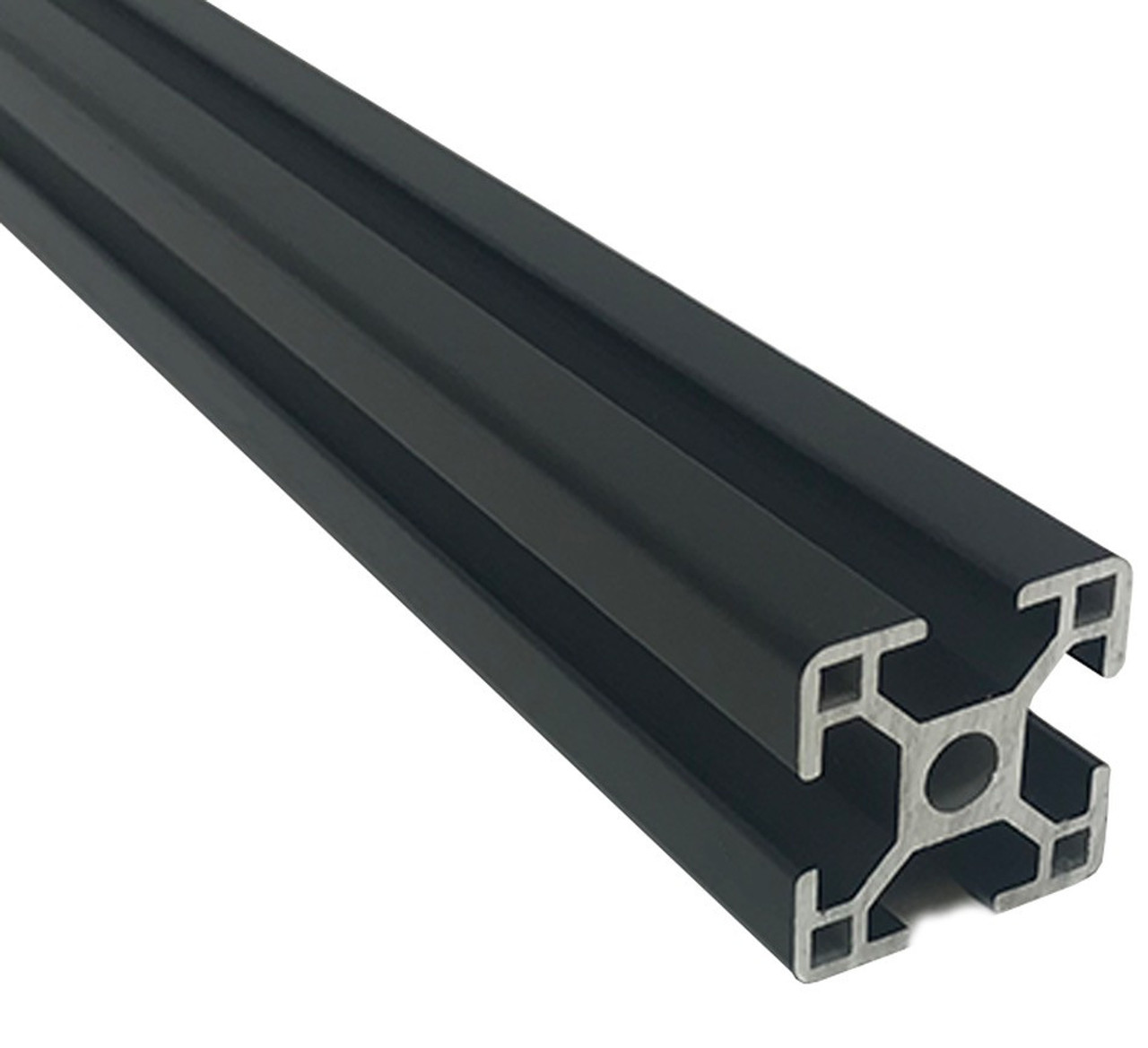

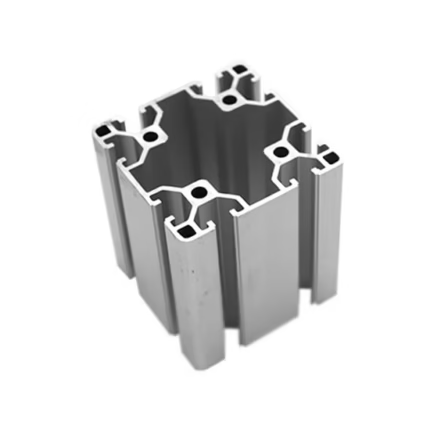

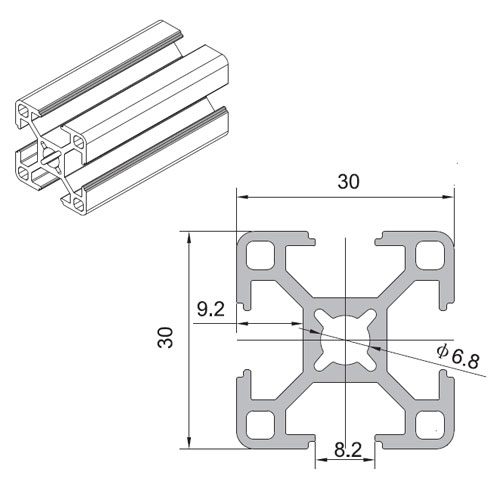

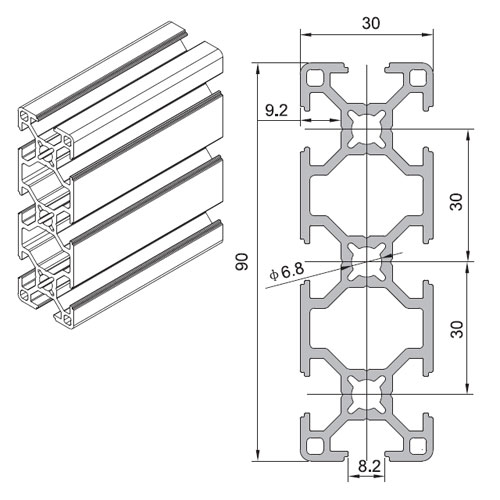

3030 T-Slot Aluminum Profile | Industrial Modular Extrusion & CNC Frame Solution

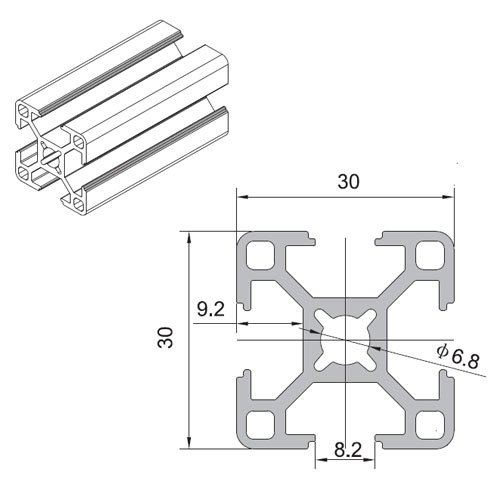

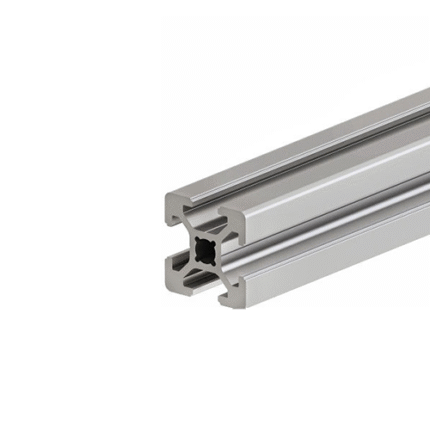

3030 profile’s slot width is 8.2 mm, and T-slot height is 9.2 mm, ideal for medium-duty, medium-stress construction, such as guarding, partitions, shelves, etc. Its appearance adopts round angle transition; the elegant surface is anodized and resists corrosion. Silver and black colors are available.

3030 Series T-Slot Aluminium Extrusion Profile often matches with M8 bolt (L=20 mm) and nut. Contact us Shanghai Slink Technology for more details

3030 T-Slot Aluminum Profile – Industrial Extrusion for Automation

Simple Description: Our 3030 T-slot aluminum profiles are designed for industrial automation frames, CNC machine enclosures, modular workstations, and production lines. With precision extrusion technology, anodized surface finish, and strict ISO quality control, these profiles offer durability, easy assembly, and a professional appearance.

Product Specifications

| Material | Aluminum Alloy T5/T6 |

| Grade | 6063, 6061, 6005, 6082, 6351, 7005, 7075 |

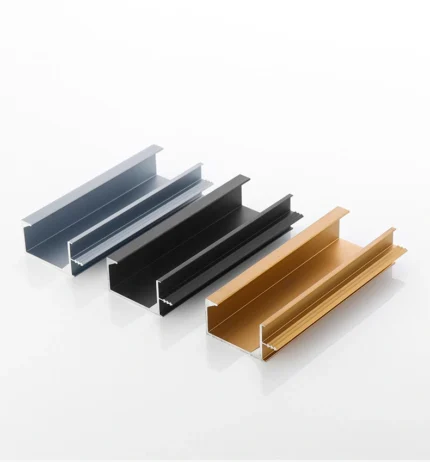

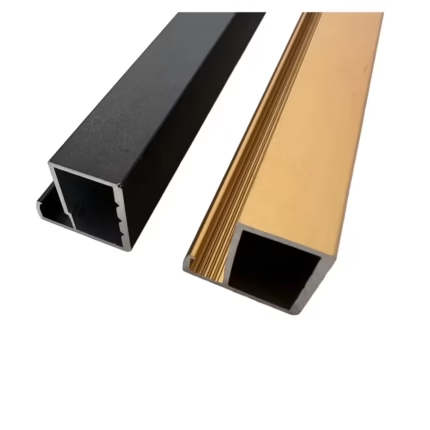

| Surface Finish | Anodized, Powder Coating, Wooden Grain, PVDF, Electrophoresis, Sand Blasting |

| Length | Standard 4–6 meters / Customizable |

| Thickness | 0.7 mm and up |

| Certification | ISO 9001:2015, SGS, ASTM |

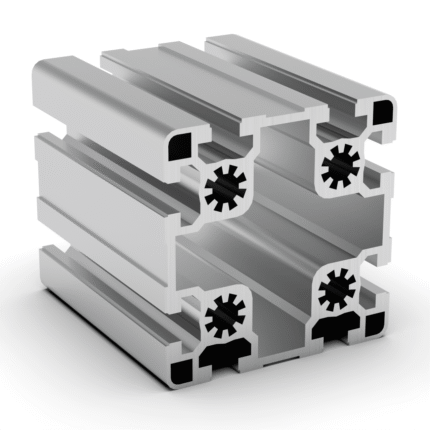

Product Images

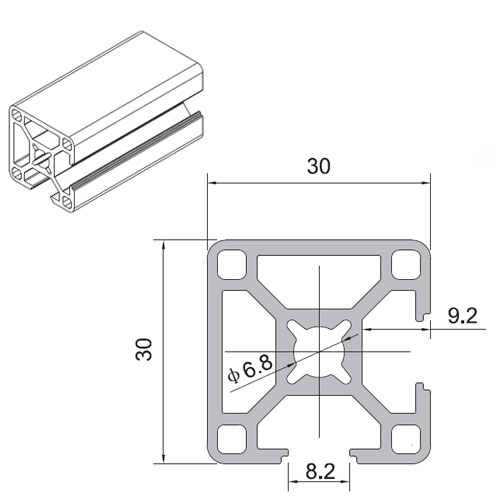

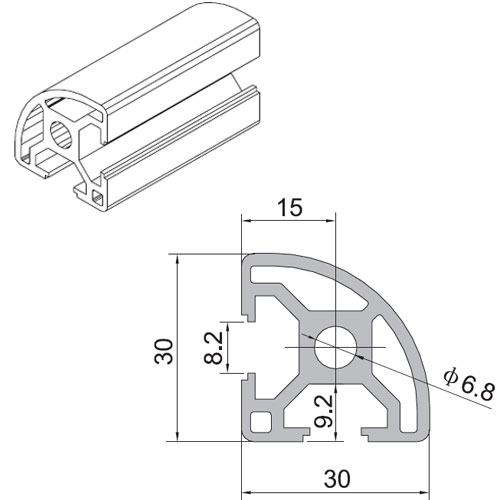

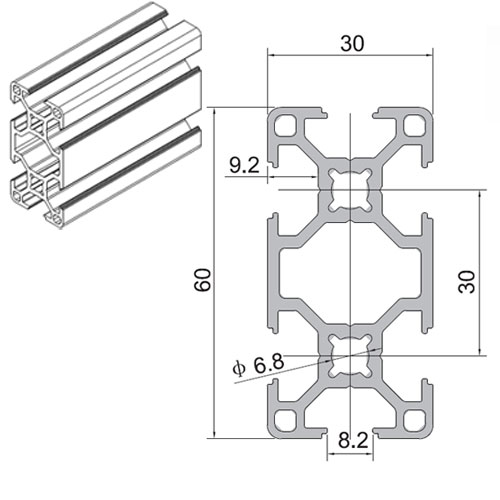

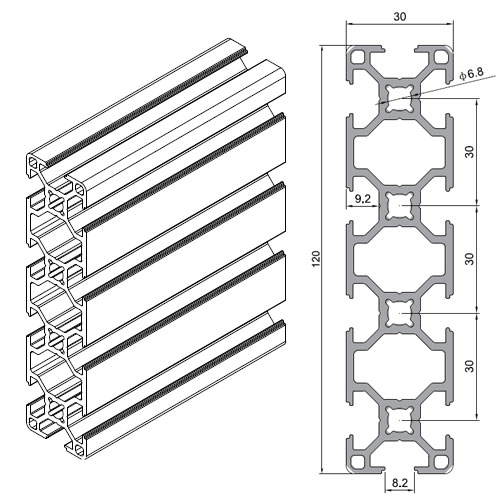

Other 30 Series Aluminium T-Slot Profiles

Applications of Slot Aluminum Profile

- Automation equipment and production lines

- Conveyor systems and assembly workstations

- 3D printer frames, CNC machine enclosures

- Exhibition stands and modular displays

- Window & Door framing applications

Key Advantages

- High Precision: Machined slots allow easy assembly and reusability

- Corrosion Resistance: Long-lasting anodized or coated finish

- Strength & Stability: Suitable for structural applications

- Customizable: Tailored lengths, CNC machining, and surface treatment available

- Compliant with SGS & ISO quality standards

Manufacturing Process

Our 3030 aluminium profiles are produced using advanced extrusion technology, including billet casting, extrusion, aging, anodizing/powder coating, precision cutting, and strict inspection to guarantee consistent dimensions and a smooth surface.

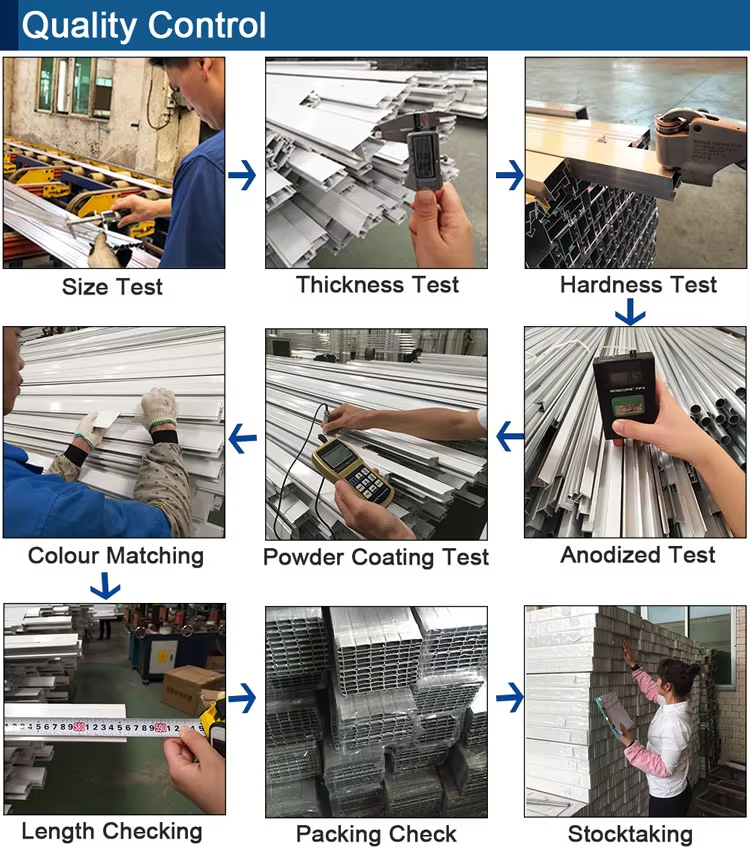

Factory & Quality Assurance

At Slink Technology, we operate multiple extrusion lines, CNC machining centers, and surface treatment facilities. Each profile is tested for strength, dimensional accuracy, and finish quality before shipment.

Quality Control

- Hardness & mechanical strength testing

- Anodizing thickness measurement

- Dimensional inspection & surface quality check

- Protective packaging and final inspection before shipment

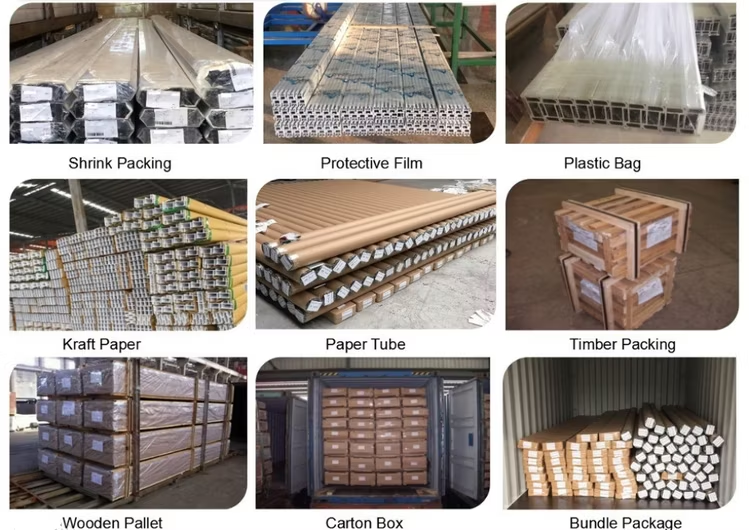

Packing & Shipping

- Protective film wrapping for each profile

- Plastic, carton, or wooden pallet outer packaging

- Safe container loading for export orders

Why Choose Us

- Certified Quality: SGS, ISO 9001, ASTM compliant

- OEM/ODM Services: Custom extrusion and machining available

- Global Export: Supplying to South America, Europe, Africa, and Asia

- Technical drawings, engineering support, and after-sales service provided

Request a Quote

Send us your DWG/STEP drawings, preferred alloy, and surface finish. We will provide professional advice, free samples, and competitive prices.

Contact us today to get your quotation.

Related Links

All Aluminum Profiles |

Cabinet Aluminum Profiles |

Window & Door Applications |

4040 T-Slot Profiles |

Contact Us