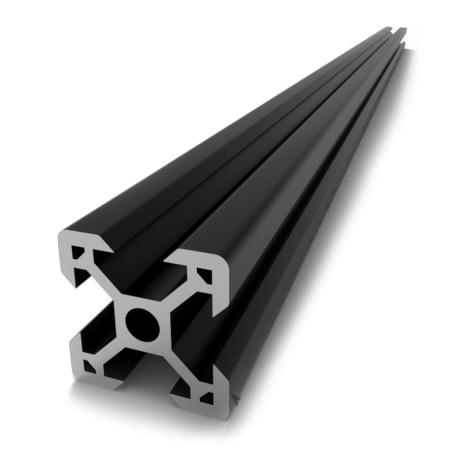

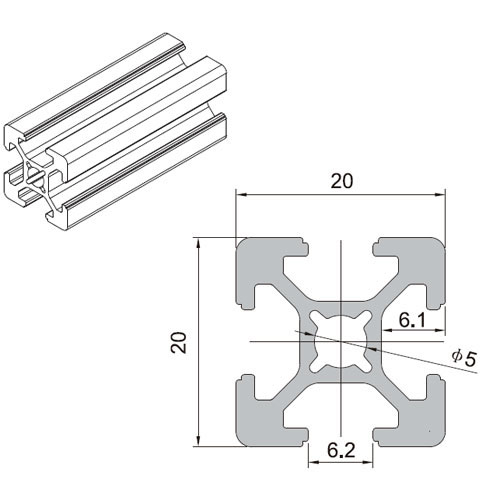

2020 T Slot Aluminum Profile | High Precision Modular Extrusion

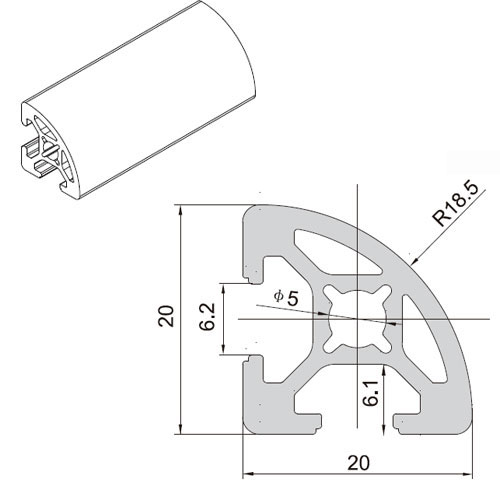

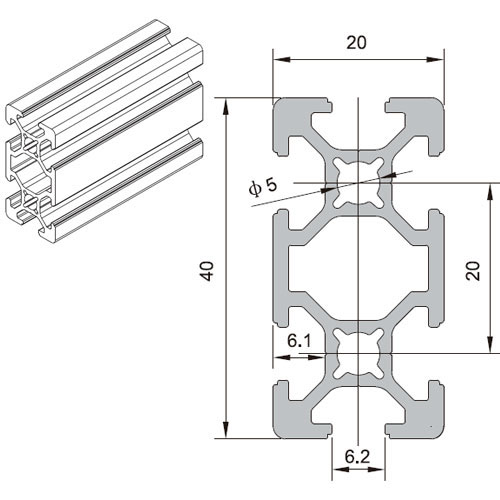

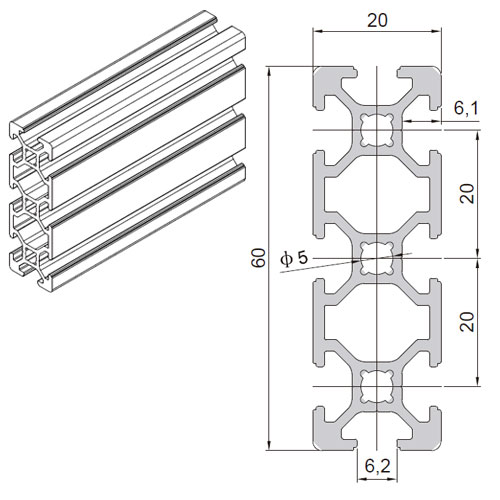

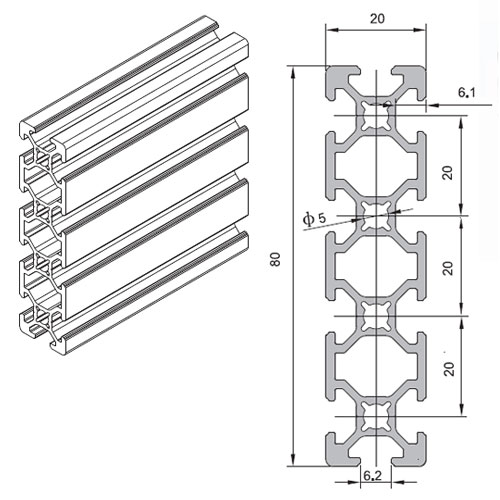

2020 profile usually applies to assembling the variety of light-weight structural framework, such as instrument rack, display board, engine cover etc. in the machinery industry. Simple and generous appearance is welcomed proverbially.

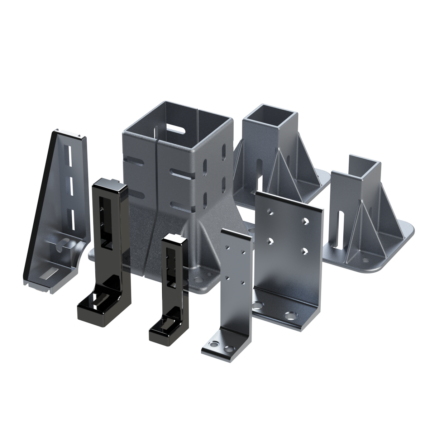

It often matches with M6 bolt (L=16 mm) of hexagon socket head and T-nut. If it needs to bear high strength, please use M6 bolt to connect with the sliding nut so that the framework much stronger and reliable. All 20 series T-slot aluminium extrusion profile can freely connect with each other.

2020 T Slot Aluminum Profile

2020 T-slot aluminium profile is widely used for modular frames, machine structures, conveyor systems, and workstations. With precision manufacturing, corrosion resistance, and customizable options, it is ideal for industrial automation and engineering projects.

Product Specifications

| Material | Aluminum Alloy T5/T6 |

| Grade | 6063, 6061, 6005, 6082, 7075 |

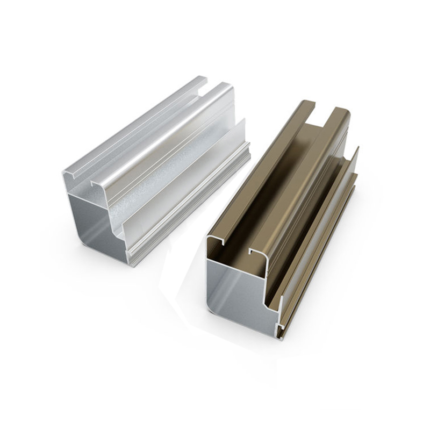

| Surface Treatment | Anodized, Powder Coated, Wooden Grain, PVDF, Sand Blasting |

| Length | Standard 4-6 meters / Customized |

| Thickness | 0.7 mm and above |

| Certificates | SGS, ISO 9001:2008 |

PRODUCT DESCRIPTION

| Material | Aluminum Alloy T5/T6 |

| Grade | Aluminum Alloy 60663, 6063A, 6061, 6005, 6060, 6165, 6082, 6351, 6013, 5083, 7005, 7075 |

| Surface | Powder coating, Anodized, Wooden Grain, Polish, Electrophoresis, PVDF, Sand Blasting |

| Length | Normal 4-6 meter / Customized length |

| Thickness | 0.7mm and up |

| Certificate | SGS, ISO 9001: 2008, ASTM |

| Advantage | Grade A material, without terrible aluminum scrap Good color looking without obvious die line, scratches, granule High precision without installation problem Strong corrosion resistance |

Applications of 2020 Aluminum Profile

- Automation equipment and production lines

- Conveyor systems and assembly workstations

- 3D printer frames, CNC machine enclosures

- Exhibition stands and modular displays

- Window & Door framing applications

Key Advantages

- High Precision: Perfectly machined slots, easy assembly without rework

- Durability: Corrosion-resistant finishes for long-term outdoor/indoor use

- Customizable: Custom aluminum profiles with different slot sizes and finishes

- Lightweight yet strong, suitable for structural frames

Manufacturing Process

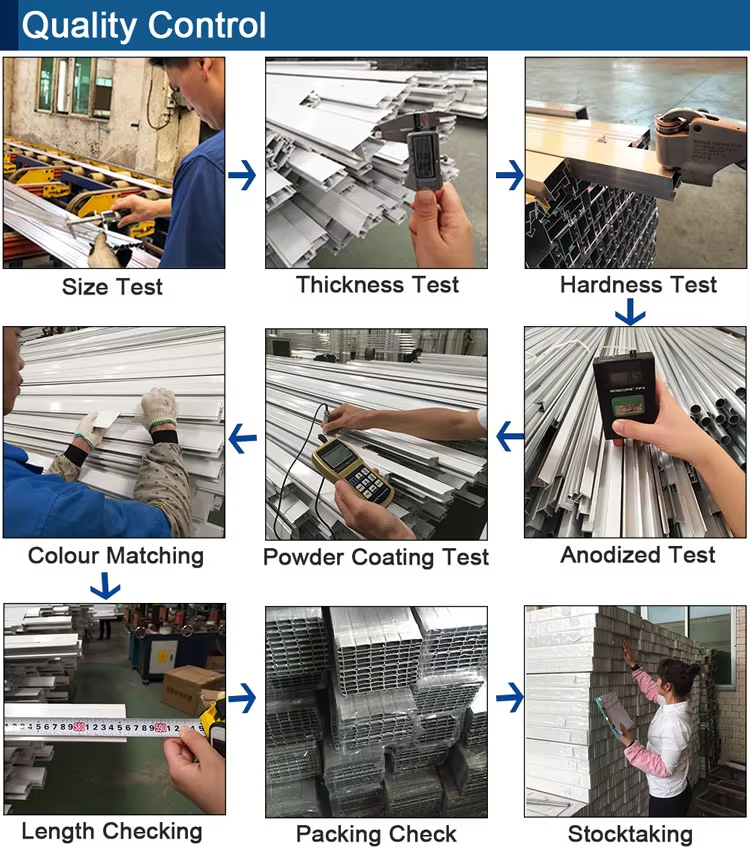

Our 2020 aluminium profiles are produced with advanced extrusion technology. Each profile undergoes billet casting, extrusion, aging, surface treatment, and precision cutting. Strict quality inspections guarantee consistency, strength, and smooth surface finish.

Factory & Quality Assurance

At Slink Technology, we operate with advanced extrusion lines and skilled technicians. Certified with ISO 9001 and SGS, we provide consistent quality and fast lead times for global customers.

Quality Inspection

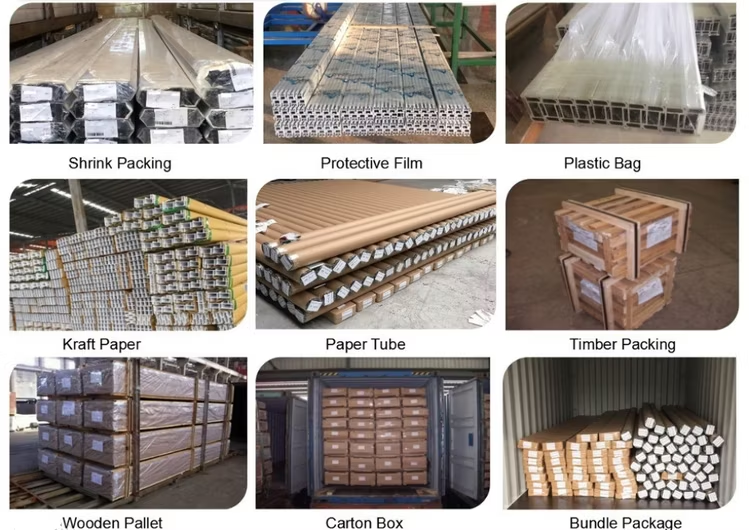

Packing & Shipping

- Protective film for each profile

- Hot shrink or plastic wrapping outside

- Carton / wooden pallet / wooden box available

Why Choose Us

- Certified Quality: SGS, ISO 9001, ASTM standards

- OEM & ODM Service: Bespoke designs available

- Global Export: Shipping to South America, Europe, Asia

- Competitive pricing, technical drawings, and after-sales support

Request a Quote

Send us your DWG/STEP drawings, preferred alloy, and surface finish. We provide professional advice, free samples, and competitive pricing. Contact us today to get your quotation.

Related Links

All Aluminum Profiles |

Cabinet Aluminium Profiles |

Window & Door Applications |

Custom Aluminum Profiles |

Contact Us