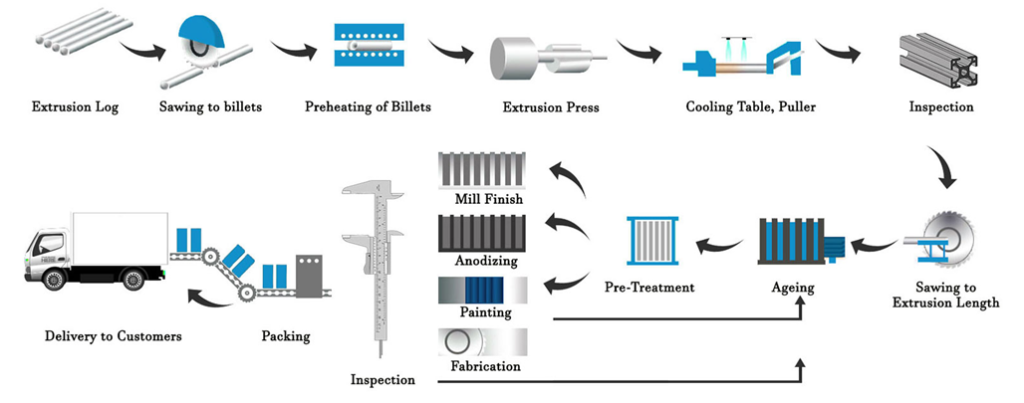

Production Process

Aluminum Production Line

Extusion

There are 10 fully equipped extrusion production lines, ranging from 6,00 tons to 5,500 tons. It can produce round aluminum tubes with a maximum diameter of 500mm, 700×50mm square aluminum tubes and various heavy industrial profiles with a round diameter of 720mm.

Each production line is equipped with high-performance equipment such as constant temperature, air cooling, water quenching, and automatic traction. It can produce various door and window extrusion profiles, curtain walls, and porous industrial extrusion profiles, with an annual output of 50,000 tons.

Anodizing

Our company has automatic horizontal and vertical anodizing production lines with anannual production capacity of 20,000 tons. Three of them are advanced verticalanodizing and electrophoretic production lines, which can work continuously fromproduct pretreatment to oxidation process, with high output, and can meet theproduction needs of different scales.

In the production process, the company pays attention to every detail, strictly complywith the process requirements and precautions, to ensure the stable operation of theproduction line and the reliability of product quality.

Powder Coating

Our company has 5 production lines of colored powder coatings with an annualproduction capacity of 30,000 tons, which can be applied to surface treatments suchas wood grain varnish, powder coatings and window seals.

We are equipped with high-precision automatic spray guns and electrostatic sprayingsystems that can evenly and delicately attach powder coatings to the surface ofaluminum profiles, ensuring the best thickness and uniformity of the coating. Theselected powder coating has excellent weather resistance, corrosion resistance andwear resistance, and can meet the needs of use in a variety of harsh environments.

Wood Grain

Our company's aluminum wood grain transfer production line is an advanced,efficient and unique production system, using high-quality wood grain transfer filmand professional transfer equipment, through precise temperature, pressure andtime control, the realistic wood grain pattern perfectly attached to the aluminumsurface, The wood grain after the transfer is clear and natural, the color is bright anddurable, and has a high degree of imitation, which can almost be comparable to realwood.

In addition, our production line is highly flexible and customized, offering a widevariety of wood grain styles and color options according to the different needs ofcustomers to meet the individual needs of various architectural decoration and homeapplications.

CNC Machining

Our company owns multiple CNC aluminum processing production lines, capable of providing customers with high-precision and high-efficiency aluminum processing services. These production lines are equipped with advanced CNC machining centers, offering powerful processing capabilities and flexible customization options. They can perform precision cutting, milling, drilling, tapping, and other processing operations on aluminum materials, ensuring processing accuracy at the micron level and guaranteeing the precision of product dimensions and shapes.

With these advanced equipment and technologies, our CNC aluminum processing production lines can provide customers with high-quality, high-precision aluminum profiles and components, widely applied in industries such as construction, automotive, aerospace, and electronics.