Powder Coating vs. Anodizing for Aluminium: Pros, Cons, and How to Choose

TL;DR

- Anodizing forms a hard, corrosion‑resistant oxide layer that integrates with the aluminium—excellent durability, metallic look, limited color depth, and best for high‑wear or outdoor architectures.

- Powder coating adds a protective polymer coating—vast colors/textures, great chemical resistance, strong edge coverage; surface is thicker and can chip if severely impacted.

- Your choice should consider environment (UV, chemicals, salt spray), aesthetics (gloss, texture, metallic feel), mechanical wear, tolerance, cost, and lead time.

Quick Comparison Table

| Criterion | Anodizing (Aluminium Anodic Oxidation) | Powder Coating (Polyester/Epoxy/Hybrid) |

|---|---|---|

| Protection Mechanism | Grows Al₂O₃ layer within/onto surface (integral) | Adds external polymer film (adherent) |

| Typical Thickness | 5–25 μm (architectural 15–25 μm) | 60–120 μm (one‑coat) |

| Abrasion Resistance | Very high (hard surface) | Good to very good (depends on resin) |

| Corrosion Resistance | Excellent when sealed; sensitive to chloride pitting if unsealed | Excellent with proper pretreatment (conversion coat) |

| UV Stability | Inorganic layer = excellent; organic dyes can fade | Polyesters: very good; epoxies: poor outdoors |

| Color/Finish Range | Natural metallic, satin, champagne, bronze, limited saturated colors | Nearly unlimited RAL/Pantone, gloss/texture/metallic possible |

| Edge & Cavity Coverage | Line‑of‑sight; inside cavities may be lighter | Very good coverage including edges |

| Dimensional Impact | Minimal; thin layer preserves tolerances | Adds significant thickness; consider fits/threads |

| Repairability | Hard to “touch up” invisibly | Local touch‑up possible with paints; full refinish best |

| Conductivity | Still conductive (reduced) unless sealed thick | Insulating polymer layer |

| Recyclability | No polymer; easy to recycle as aluminium | Coating must be burned off before remelt |

| Typical Uses | Architectural extrusion, door/window, electronics, wear parts | Machinery guards, outdoor furniture, façades, color‑critical branding |

How Each Process Works

Anodizing

Electrochemical process in acidic electrolyte that thickens the natural oxide on aluminium. After growth, pores are dyed (optional) and sealed (hot water/nickel acetate/steam). The layer is integral to the base metal—no peeling.

Common types

- Decorative/architectural: 10–25 μm, dyed or clear, sealed.

- Hard anodizing: 25–80 μm, high wear/low friction, typically grey/brown.

Powder Coating

Electrostatic deposition of dry powder onto pretreated aluminium, followed by oven curing to cross‑link the resin. Pretreatment often includes degrease → etch → conversion coat (chromate‑free zirconium/ titanium/ phosphate) to ensure adhesion and corrosion resistance.

Common powders

- Super‑durable polyester (TGIC‑free): best for UV/architectural façades.

- Standard polyester: general outdoor.

- Epoxy: indoor, chemical resistance, poor UV.

- Polyurethane/hybrids: specialty textures.

Advantages & Disadvantages

Anodizing – Advantages

- Exceptional wear resistance and hardness; ideal for sliding/handling surfaces.

- Stable metallic appearance that highlights alloy and brushing/graining.

- High UV and heat resistance; will not chalk like some paints.

- Thin build preserves tight fits and thread engagement.

- Environmentally lean finish (no solvent; metal‑only waste streams).

Anodizing – Limitations

- Color range is limited; deep, saturated, or bright colors are harder to achieve.

- Color consistency can vary across batches/alloys; visible lot‑to‑lot shift.

- Chloride environments (marine/pool) can cause pitting if sealing is poor.

- Touch‑up is difficult; damaged areas usually require re‑anodizing.

Powder Coating – Advantages

- Unlimited color/texture (RAL/Pantone, matte to high gloss, wrinkles, metallics).

- Excellent edge/corner coverage and uniform appearance on complex frames.

- Robust corrosion resistance with proper pretreatment and film thickness.

- Repairable via local touch‑up paints or partial refinish.

- Cost‑effective for color branding and visual differentiation.

Powder Coating – Limitations

- Film thickness affects tolerances; plan clearances for sliding fits/slots.

- Possible chipping under sharp impact; reveals metal underneath.

- UV durability depends on powder type (avoid epoxies outdoors).

- Heat exposure during cure may affect pre‑assembled components/gaskets.

Application‑Driven Selection Guide

Harsh UV + Coastal (façades, railings, outdoor structures)

- Preferred: Super‑durable polyester powder or architectural anodizing ≥20 μm, well‑sealed.

- Consider: Duplex systems (anodize + powder) for extreme corrosion and color needs.

High Wear / Sliding / Handling (fixtures, guides, workbenches)

- Preferred: Hard anodizing (≥25 μm).

- Avoid: Thick powder on sliding interfaces; use masks or post‑machining.

Tight Tolerances (machined frames, precision jigs)

- Preferred: Anodizing for minimal build; specify final dimensions considering growth (~½ thickness penetrates substrate).

- If powder: Mask critical bores/threads; open tolerances accordingly.

Color‑Critical Branding (showroom frames, retail, furniture)

- Preferred: Powder coating for repeatable colors, gloss control, and textures.

EMI/Conductivity Needs (grounding points, housings)

- Preferred: Masked areas or thin anodize left unsealed; powder is insulating.

Quality & Specification Tips

- Alloy & temper matter: 6063 gives best anodic appearance; 6061/6005 may tint darker.

- Surface prep defines the look: mechanical brushing, polishing, bead blasting change reflectivity under both finishes.

- Anodize specs: thickness (μm), sealing method, color code, ISO/AA designation.

- Powder specs: resin chemistry, gloss level, texture, film thickness (μm), curing schedule, and salt‑spray/UV class (e.g., AAMA 2603/2604/2605).

- Pretreatment is non‑negotiable: insist on certified conversion coatings for powder; for anodize, control bath chemistry and sealing quality.

- Samples first: approve color chips and production coupons from the same alloy/batch.

Maintenance & Lifespan

- Anodized surfaces: clean with mild detergent and water; avoid strong alkalis or chlorides. Lifespan can exceed decades in architecture when sealed and maintained.

- Powder‑coated surfaces: routine neutral‑pH washing; avoid abrasive pads. Recoat possible without stripping in some cases, but best practice is strip → recoat.

Cost & Lead Time (General Guidance)

- Anodizing often has lower material cost per m² at thin films and fast cycle times; color matching and long lengths may increase handling time.

- Powder coating adds cost for powder, curing energy, and masking, but consolidates color + protection in one step; color changeovers can affect lead time for small batches.

Environmental Considerations

- Anodizing uses electrolytes and produces metal‑hydroxide sludge; modern lines recycle water and control effluents. No organic polymers added.

- Powder coating is solvent‑free and overspray is reclaimable; however, coated scrap must be burned off before remelting.

Frequently Asked Questions

Q1. Can I combine both?

Yes. A duplex system (anodize + powder) delivers outstanding corrosion resistance and color range, used in premium façades and marine hardware.

Q2. Will colors match across batches?

Anodize can vary with alloy/batch and bath conditions; powder offers tighter batch‑to‑batch color control. Always approve a master sample.

Q3. What about threads and tapping?

Mask threads before powder coating; for anodizing, consider post‑tap or specify fit class that accommodates oxide growth.

Q4. Are there maximum lengths?

Yes—both processes depend on tank/oven size. For long extrusions, check line capacity (e.g., 6–7 m typical) and plan joints.

Conclusion

If you need metallic aesthetics, thin build, and abrasion resistance, choose anodizing. If you need rich colors, textures, and edge coverage on complex assemblies, choose powder coating. For severe marine or landmark projects, consider a duplex approach. The best outcome comes from aligning finish selection with environment, function, and assembly method—early in design.

Work With Shanghai Slink Technology

We provide end‑to‑end finishing for aluminium extrusions: surface preparation, anodizing (decorative & hard), and powder coating with architectural‑grade chemistries. Share your drawings, target environment, and color goals—we’ll propose the right finish, samples, and a production plan.

Capabilities & Certifications (Fill with your actual data)

- Line capacity (max length): up to 6–7 m extrusions (verify against your shop limit).

- Anodizing thickness: decorative 10–25 μm (typical), hard 25–60 μm (project‑dependent).

- Powder film build: 60–120 μm in one‑coat; duplex (anodize + powder) available on request.

- Pretreatment: chromate‑free conversion coatings (zirconium/titanium) for adhesion & corrosion resistance.

- Standards we can build to: AAMA 2603/2604/2605 (powder), Qualicoat (powder), Qualanod (anodize) — specify class in PO.

- Quality system: ISO 9001 (enter certificate no. here).

- Color control: RAL/Pantone master chips retained for lot traceability.

Contact

- Company: Shanghai Slink Technology Co., Ltd.

- Email: info@aluslink.com (replace with your official email)

- Phone/WeChat/WhatsApp: +86‑15209818007

- Samples: lead‑time typically 3–7 days after spec confirmation (update with real SLA).

Visual Asset Pack (for your designer)

- Process diagrams: anodizing flow (clean → etch → anodize → dye → seal); powder flow (degrease → etch → conversion → spray → cure).

- Thickness infographic: 10–25 μm vs 60–120 μm with callouts on tolerance/fit.

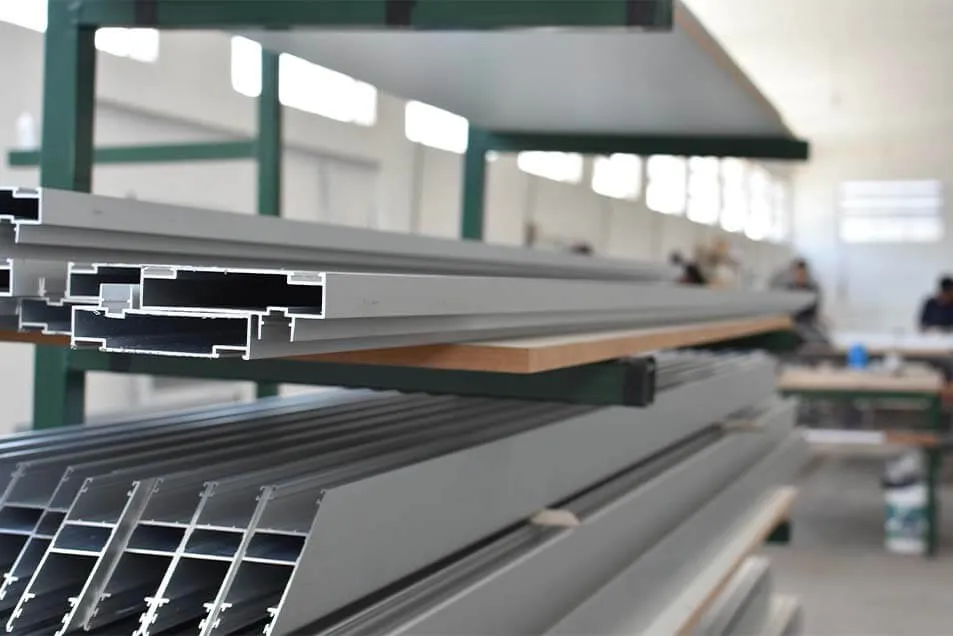

- Application photos: façades near coast, machine guards, workstations, door/window frames.

- Detail shots: edge coverage comparison, masked threads

slot profiles very good

Very good quality