Custom Heatsink Aluminum Profile | Extrusion & CNC Machining Manufacturer

High-performance heatsink aluminum profiles for power supply, and industrial cooling systems. Custom extrusion & CNC machining with ISO/SGS quality assurance. Global supply and competitive prices.Aluminum extrusion heat sinks are an effective way to cool heat producing components in a cost-effective manner.Aluminum extrusion heat sinks can also be customized with embedded heat pipes, captive mounting hardware, and color anodizing.

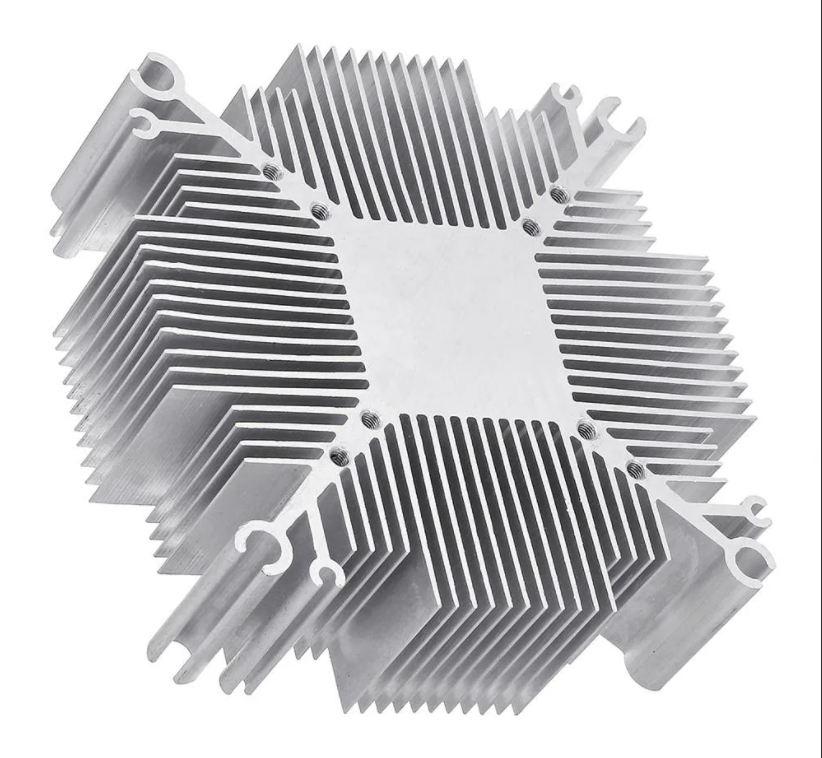

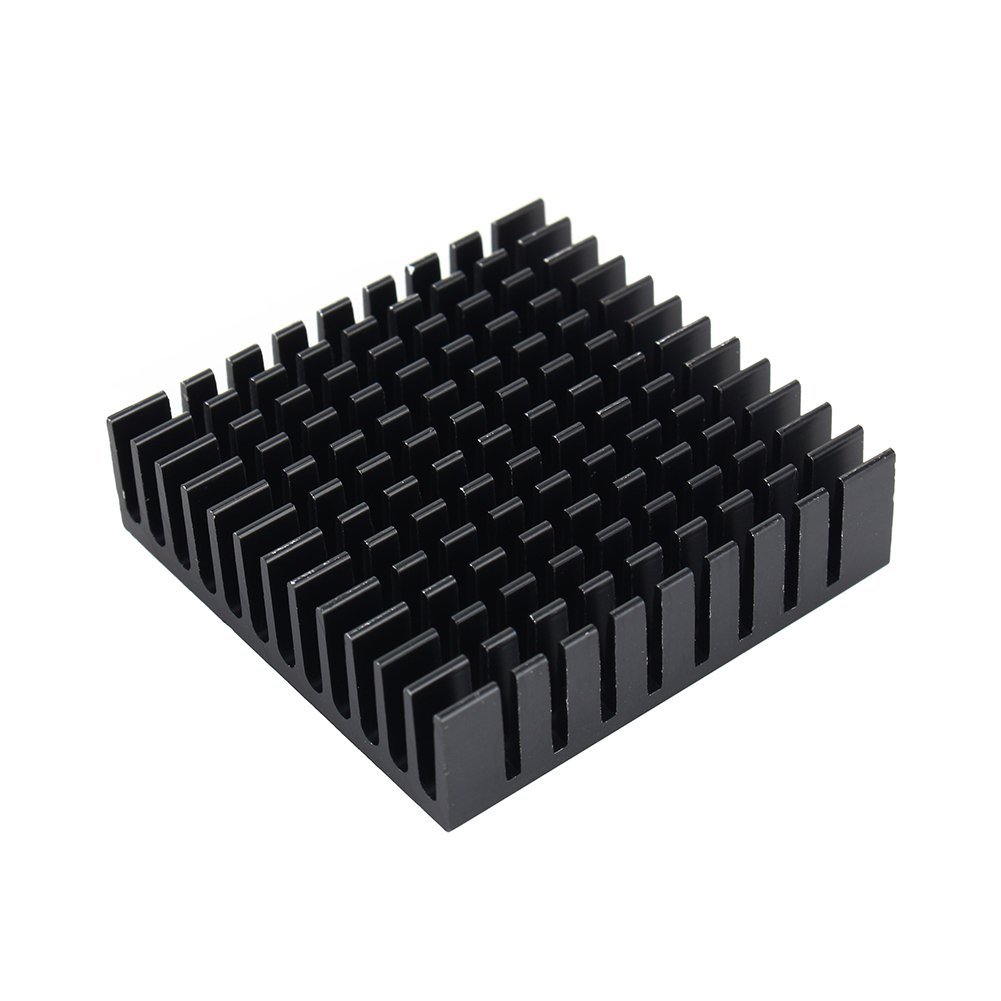

Custom Heatsink Aluminum Profile

Slink Technology provides precision-engineered heatsink aluminum profiles for efficient heat dissipation in electronics, LED lighting, power supply units, and industrial machinery. Our extrusion and CNC machining services ensure consistent quality and perfect fitting for your cooling requirements.

Product Description

| Material | Aluminum Alloy T5/T6 |

| Grade | 6063, 6061, 6005, 6082, 6060 (Customized on request) |

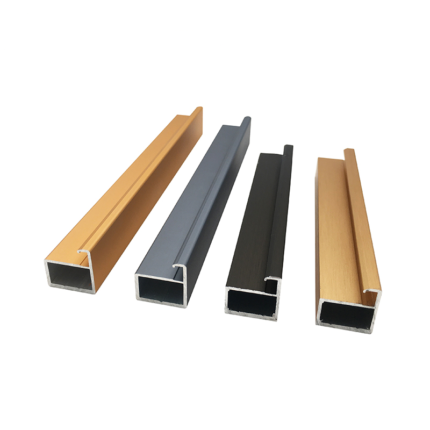

| Surface Finish | Anodizing, Sand Blasting, Powder Coating, Electrophoresis |

| Length | 4–6 meters standard / Custom cut lengths available |

| Thickness | Customized from 0.7mm and above |

| Certification | ISO 9001, SGS, RoHS compliance |

| Advantages | Excellent thermal conductivity, corrosion resistance, lightweight yet strong structure |

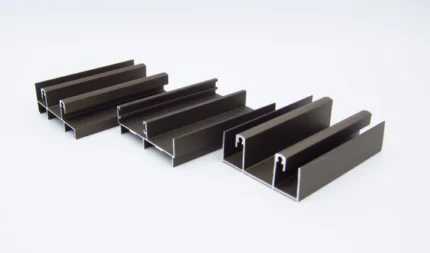

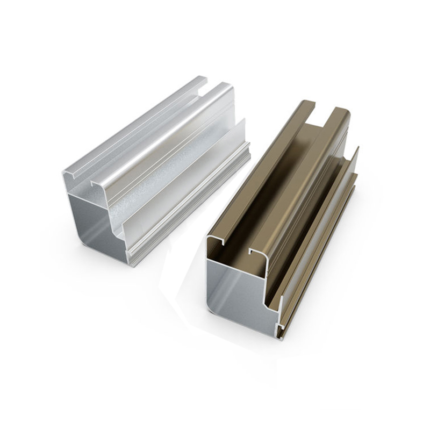

Product Display

Applications

- LED lighting heat dissipation

- Power supply and inverter cooling

- Industrial machinery and automation equipment

- Electronic enclosures and control panels

- Telecom and server cooling systems

Factory & Production Process

Our Slink Technology factory is equipped with advanced extrusion presses, surface finishing lines, and precision cutting machines. From billet casting to extrusion, heat treatment, and surface coating, every step follows ISO & SGS-certified standards.

Why Choose Slink Technology

- Direct manufacturer with ISO & SGS certification

- Customizable extrusion and CNC machining

- Global export experience: Europe, USA, Asia, Middle East

- Fast lead times and professional technical support

Manufacturing Process

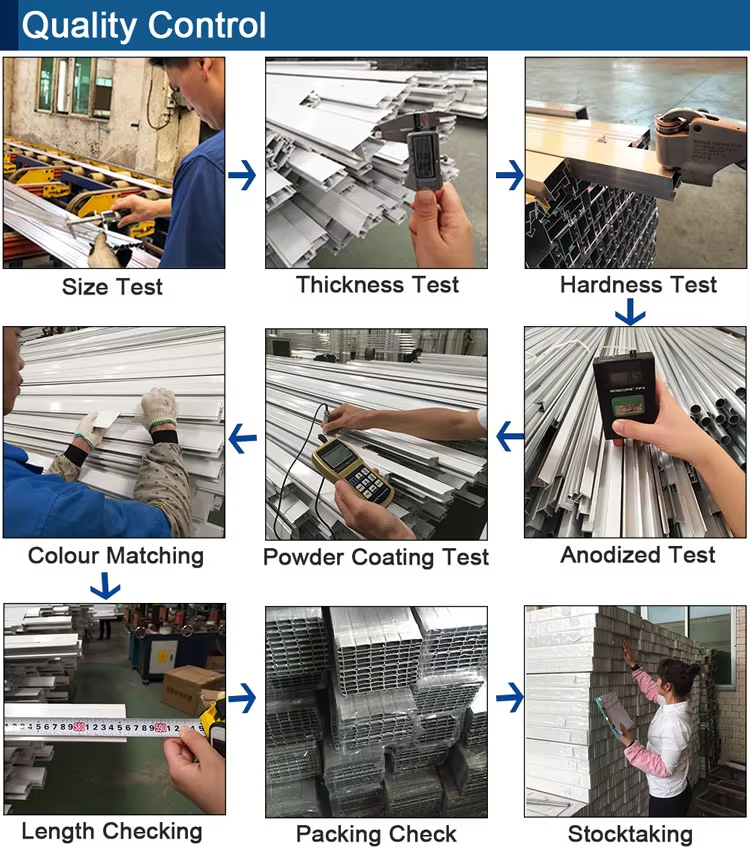

Our aluminum extrusion process is followed by precision CNC machining, anodizing, and strict quality control to ensure optimum thermal performance and long service life.

Quality Control

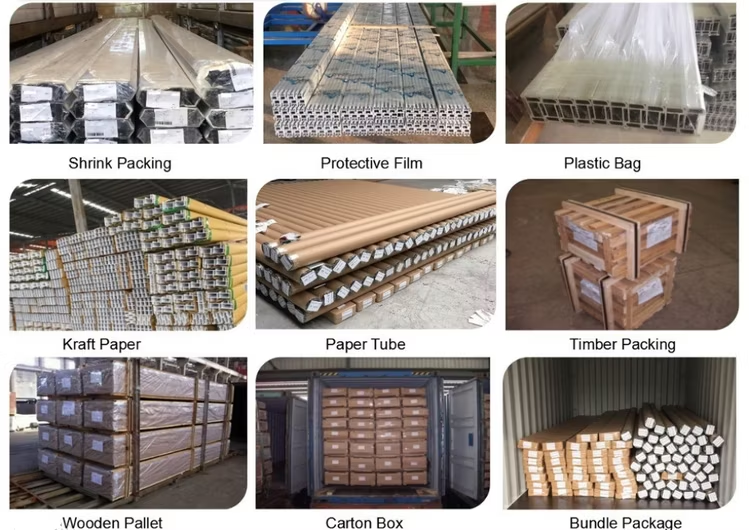

Packing & Shipping

Standard export packaging with foam, shrink film, and pallets ensures safe delivery worldwide.

Request a Quote

Send us your DWG/STEP drawing, required alloy, and surface finish. Our engineering team will provide optimized solutions and competitive prices. Request a free sample now.

Explore More

Cabinet Aluminium Profiles |

Window & Door Profiles |

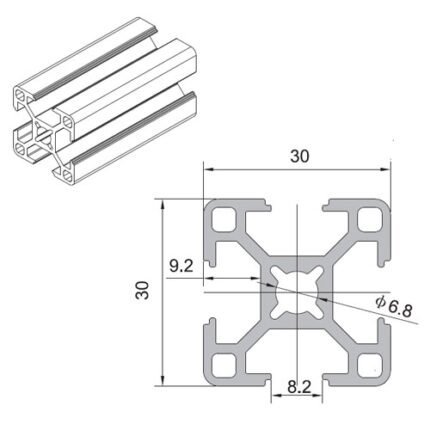

T Slot Aluminium Profiles |

Contact Us